Our services

AMufacture operates an ecosystem of best-in-class production and finishing facilities with end-to-end part traceability and repeatability. Our dedicated assembly lines serve as an extension to your workflow, delivering parts to your specifications.

Our 3D printing technologies

What is the right solution for your business?

Collaborate with AMufacture's in-house specialists to understand how additive manufacturing can optimise your workflow and advise which technology solution, material and finishing suits your requirements.

As your contract manufacturing partner, we offer a wide range of 3D printing technologies and materials, including in-house capabilities with MJF, DLP, SLS, SLA and FDM. We also operate and manage traditional manufacturing processes such as CNC and injection moulding.

We specialise in HP Multi Jet Fusion (MJF) as this technology meets the high specifications and requirements of our clients with respect to part performance, scalability and lead time.

Durable engineering grade materials

AMufacture specialises in the use of engineering materials, with a focus on HP 3D High Reusability Nylon PA12 and HP PA12 White. This provides design freedom for our clients to develop functional end-use isotropic parts, capable for production at scale.

Other engineering grade materials are offered by AMufacture to meet your specifications (including PA11 and TPU), please contact us for more information.

Some of our industry applications:

Defence Sector

Additive Manufacturing is transforming defence—redefining how equipment is designed, produced, and sustained.

At AMufacture, we combine advanced processes with one of the UK’s largest HP Multi Jet Fusion fleets to collaborate at a Tier 1 partner to deliver rapid prototyping, production, and mission-ready parts. With automated build-unit changeover and 24/7 uptime, we ensure operational resilience - not simply “just in time,” but more importantly “just in case.”

From new product introduction to on-demand spares, our programmes are built on full traceability, comprehensive quality control, and a proven, resilient supply chain. Forces can rely on us for repeatable parts, wherever and whenever they’re needed.

Our expertise in lightweight, high-performance materials enables tailored solutions for drones, UAVs, UGVs, AUVs, and exoskeletons—improving performance, reducing weight, and accelerating readiness.

Defence Sector

Marine

AMufacture's expertise in the marine industry has been driven by co-founder and COO, Will Howden, a qualified naval architect after a successful Olympic sailing career.

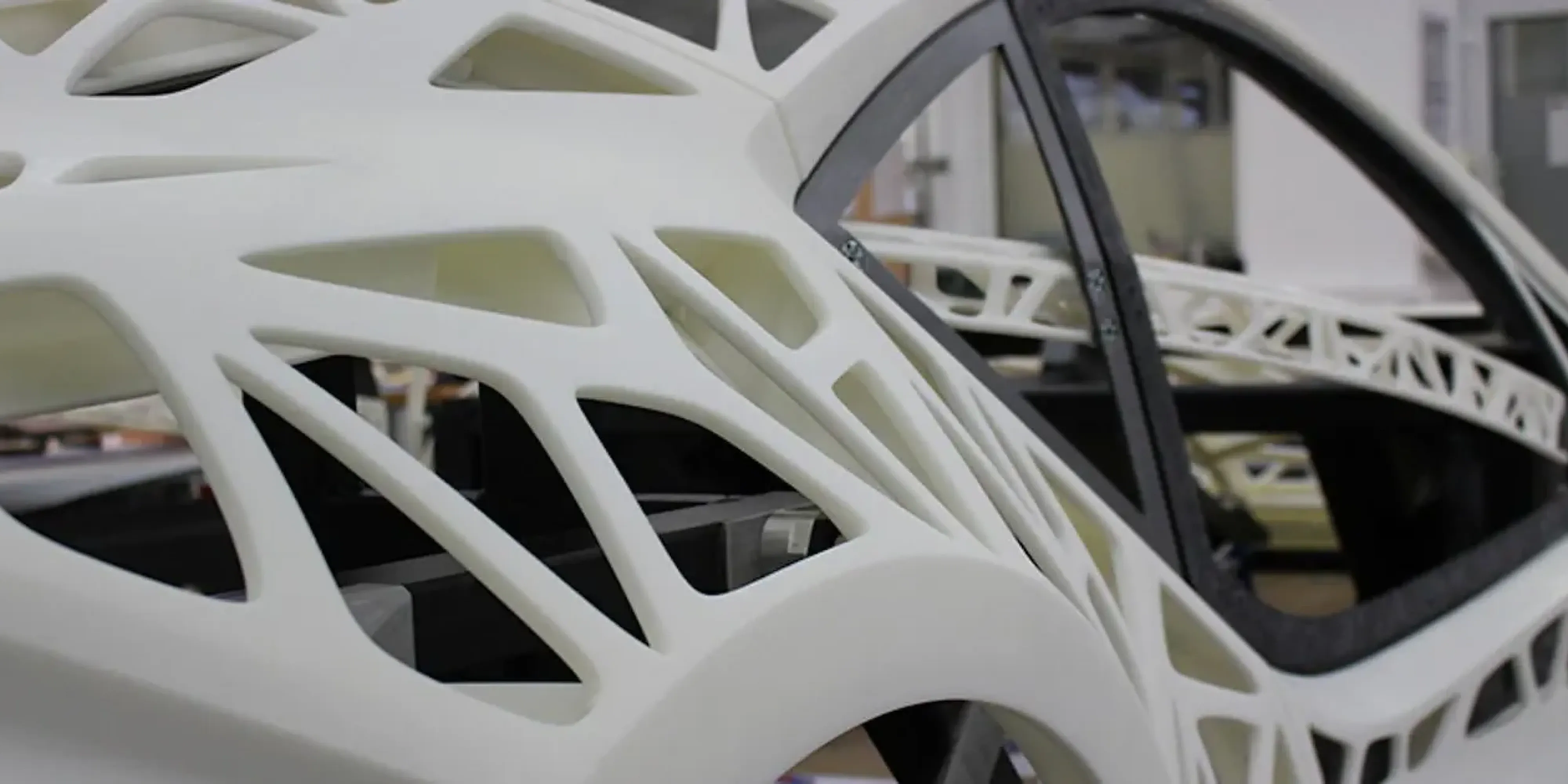

Our experience working within this sector has involved design optimisation and manufacturing of parts to be included in luxury and racing yachts to commercial vessels. Part applications range from pedal mechanisms and grey water manifolds to water strainers and external painted parts.

As a Tier 1 supplier, AMufacture has developed specialised quality controlled workflows to adhere to the strict specifications relating to marine part performance, aesthetics and scaled production. To meet this demand, AMufacture has expanded in-house capabilities and expertise, which have now been applied across clients and sectors.

Marine

Automotive

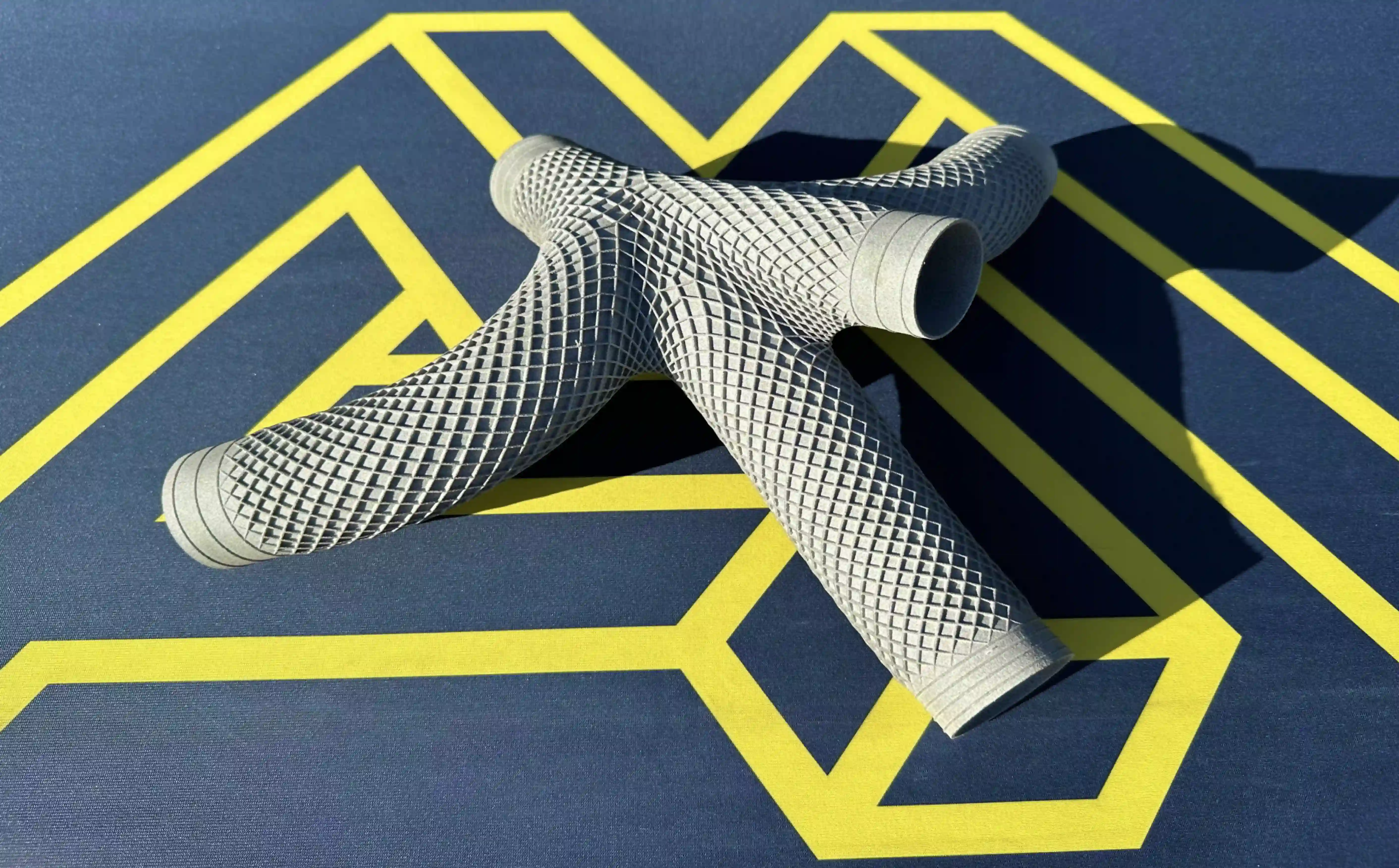

AMufacture has experience in collaborating with major automotive OEMs to optimise pre-production, bridge and ramp-up production. Our capabilities range from prototype parts and interior cockpit plastics to full HVAC systems, general air ducts, break ducts, under bonnet components, cable saddles and hose saddles.

Additive manufacturing technology has successfully been integrated within automotive production at scale, recently demonstrated by Toyota's first mass-produced 3D printed certified part. This was the automatic transmission oil cooler ducts manufactured through MJF technology, included within the Lexus LC500, using 37% less greenhouse gas emissions compared to injection moulding.

Automotive