Additive Manufacturing

Discover HP's Multi Jet Fusion (MJF) technology: a fast, scalable, and sustainable additive manufacturing method for creating complex, isotropic, and functional 3D parts with precision and efficiency.

Multi Jet Fusion (MJF)

MJF is the proprietary technology of HP, developed in 2016, and has advanced the additive manufacturing industry through an efficient, scalable and sustainable manufacturing method to produce repeatable, functional and isotropic parts.

MJF is a powder-bed fusion technology which prints thermoplastic powder in layers of 80-micron thickness, incorporating fusing agents and heat to print multiple parts simultaneously. The unfused powder supports your parts during printing so you can create complex, interconnecting designs with no need for support structures.

What is MJF?

MJF is the proprietary technology of HP, developed in 2016, and has advanced the additive manufacturing industry through an efficient, scalable and sustainable manufacturing method to produce repeatable, functional and isotropic parts.

MJF is a powder-bed fusion technology which prints thermoplastic powder in layers of 80-micron thickness, incorporating fusing agents and heat to print multiple parts simultaneously. The unfused powder supports your parts during printing so you can create complex, interconnecting designs with no need for support structures.

MJF is ideal for functional prototypes and complex end-use parts for scale production. Optimised designs, for instance through latticing for enhanced strength and reduced weight, can be printed without additional lead time or cost.

Sustainability is a key benefit of this manufacturing technology, with 75% recycled polymer being utilised in every build compared to 30-50% recycled in SLS.

AMufacture operates two HP Jet Fusion 5210 printers and an HP Jet Fusion 5420 White printer to become the first UK contract manufacturer to produce white MJF parts, unlocking finishing freedom through vibrant dyes.

As a partner in the global HP Digital Manufacturing Network, HP has recognised AMufacture as delivering best-in-class MJF part quality and end-to-end production capabilities.

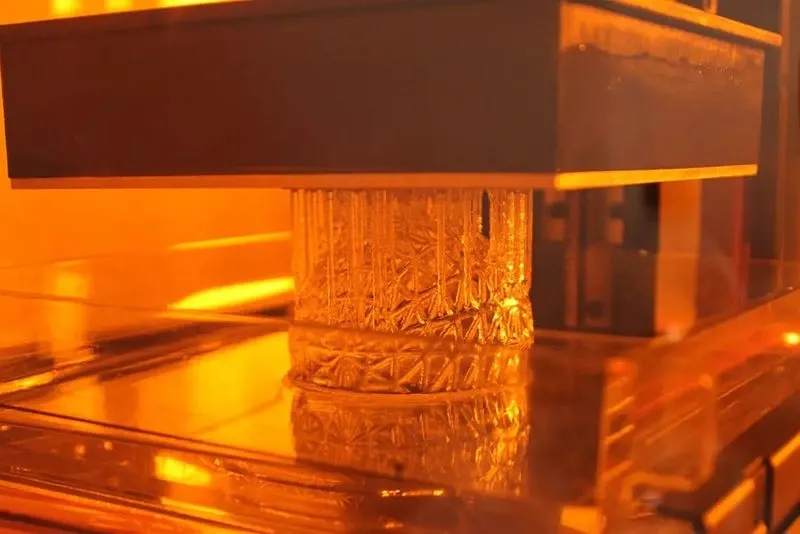

Digital Light Processing

DLP selectively cures a photopolymer resin in layers by using a projector and digital mirror device to concentrate patterned UV light on a build plate. This resin-based 3D printing technology, similar to SLA, can be used to print in a range of materials with a variety of mechanical properties.

SLS

Selective Laser Sintering (SLS) is an established powder bed fusion technology that uses a high-powered laser to melt and fuse layers of thermoplastic powder. Similar to MJF, unsintered powder supports your parts during printing so you can create complex, interconnecting designs with no need for support structures.

Stereolithography (SLA)

SLA uses a UV laser to cure a liquid resin in a resin tank (vat). The laser is used to cure the resin with great accuracy layer by layer until the build plate moves up by 1 layer and the process starts again until the part is finished. With SLA you can 3D Print strong and homogenous parts with great mechanical properties.

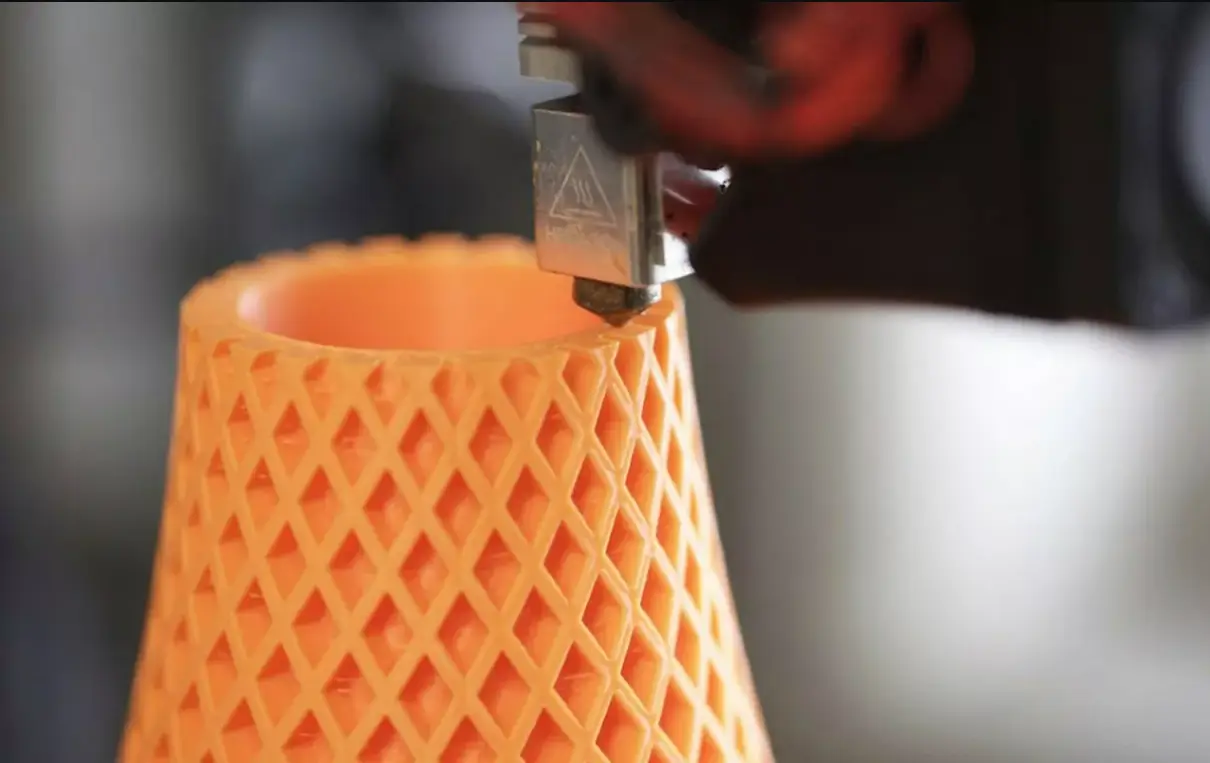

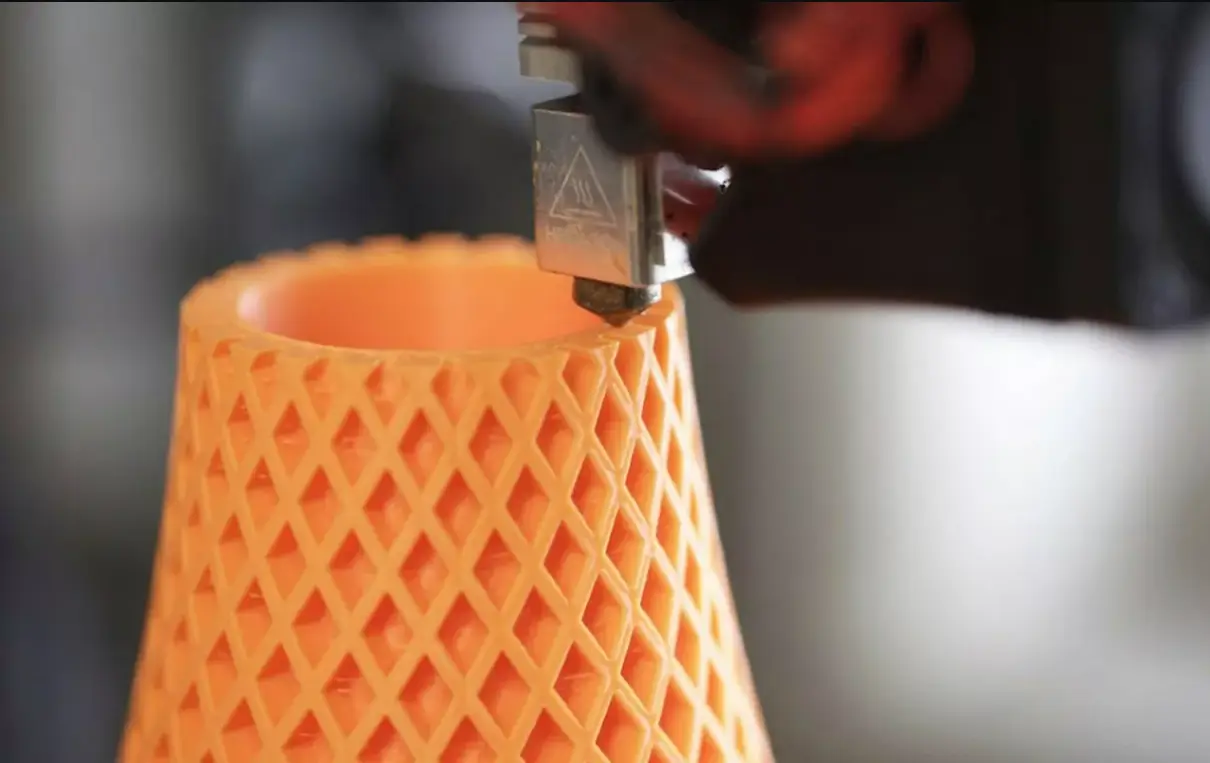

Fused Deposition Modelling (FDM)

FDM is an accessible and proven 3D Printing technology. FDM provides rapid turnaround, short lead times and a large range of colour and materials. FDM is most suited to simple geometric designs.